The rock, the gesture and the tool

The rock

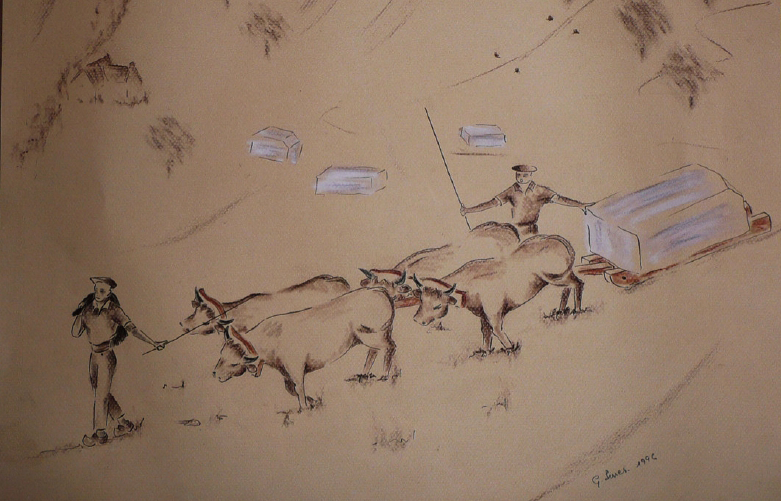

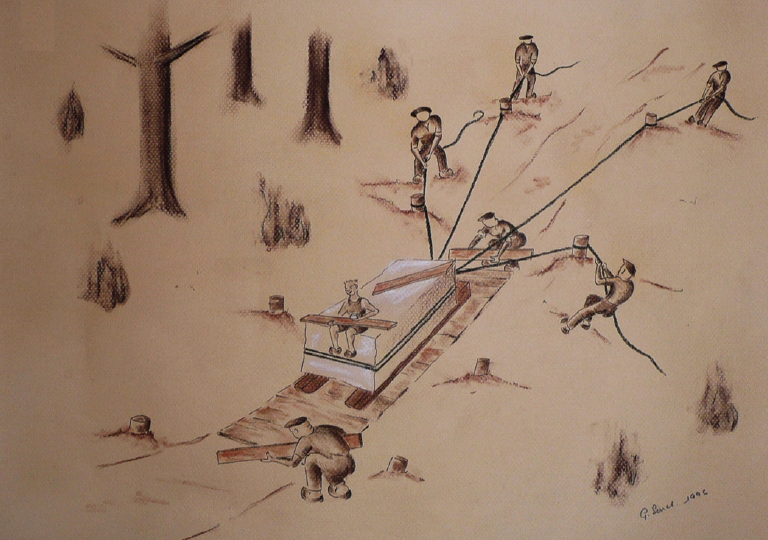

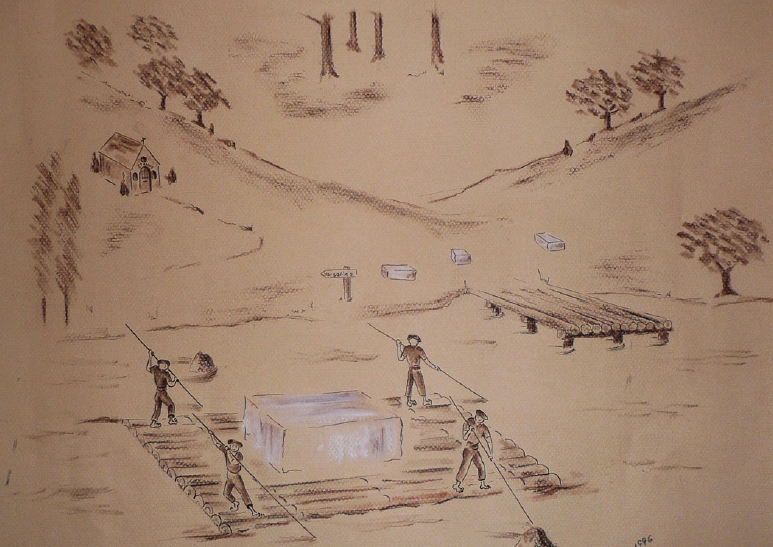

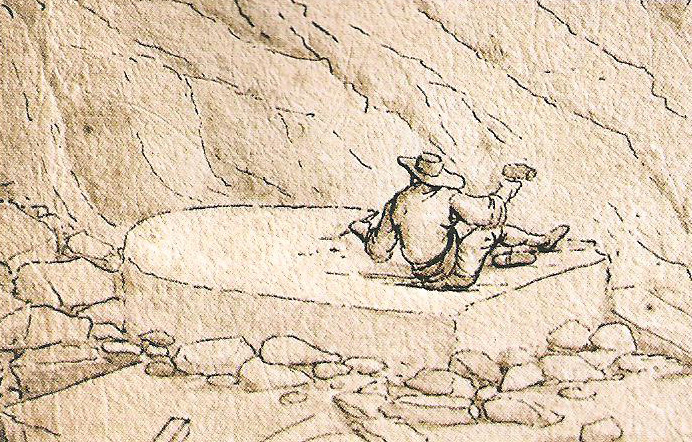

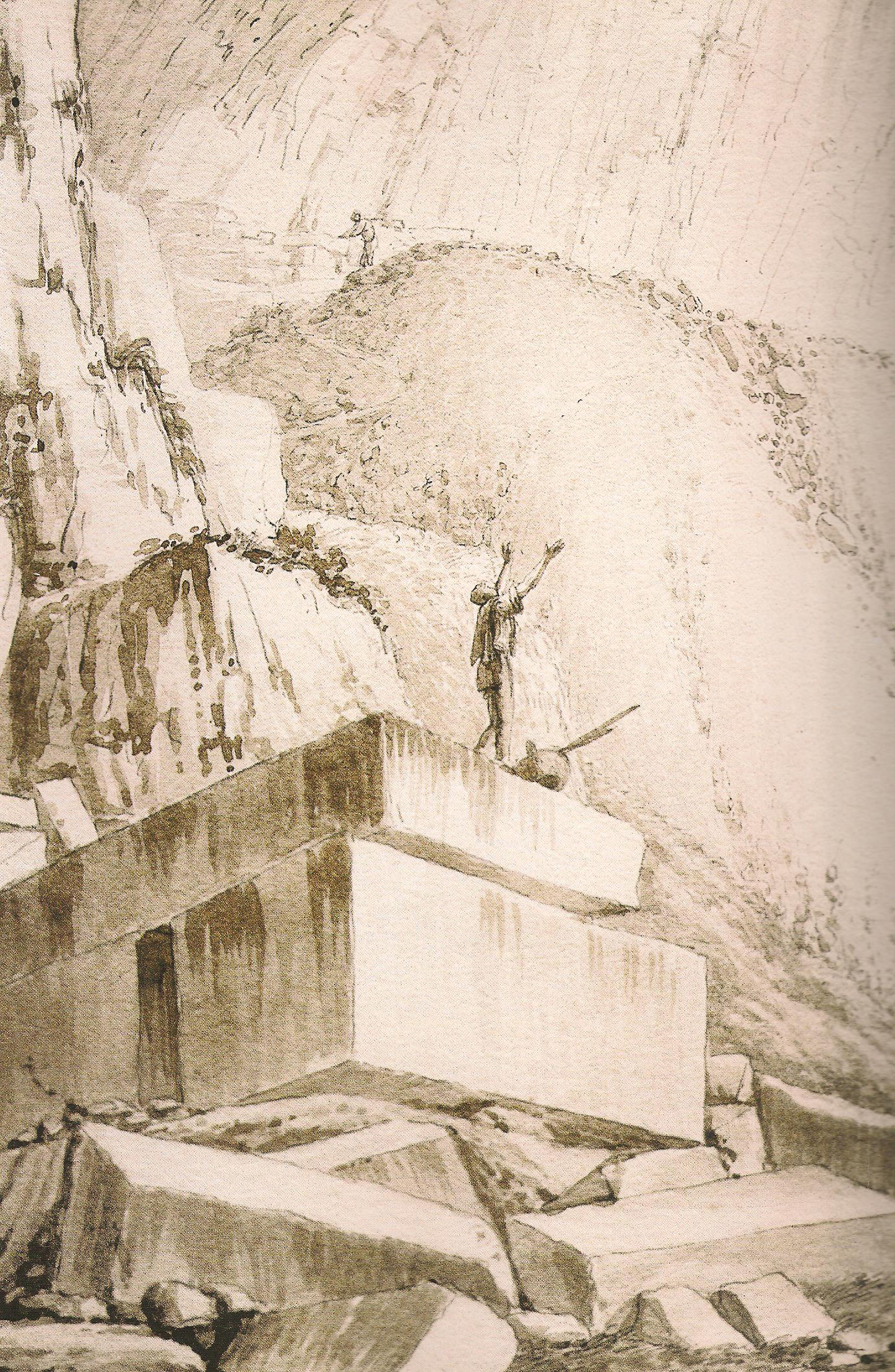

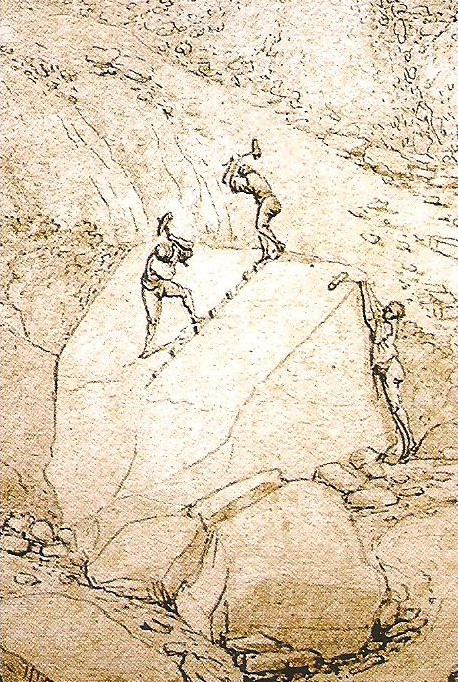

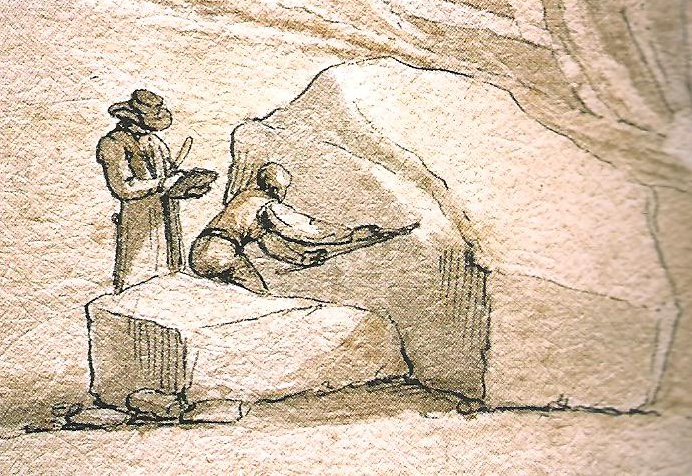

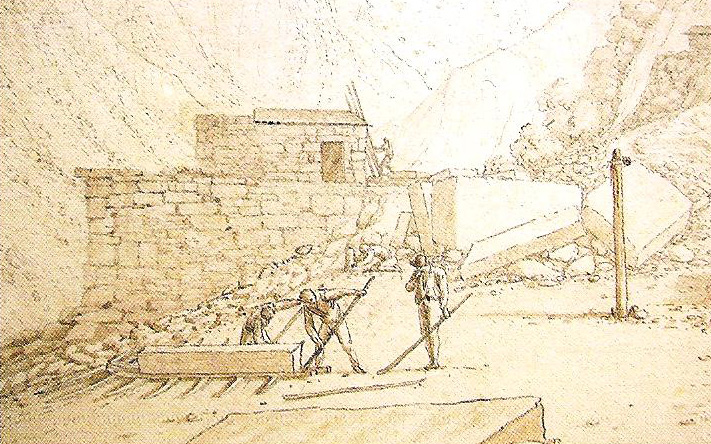

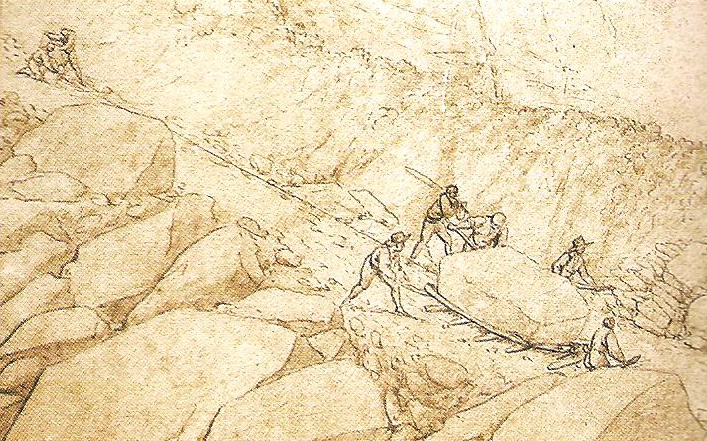

To update then implemented of the marbles was done using processes and of techniques tested with the wire of the ages, unceasingly transmitted and improved. Borings of the mine splits up the matter, breadths glares of the peak which releases it., the sharp striations of the points which open it and equalize it: each stage of a slow change printed deep or light brands, those of the gesture which achieves, dimension hidden, forgotten but colossal and deeply human of work to come.

The marble is by layers and masses, which are sometimes very thick and very considerable; those which are closest to the surface of the ground are commonly the least good, being filled of slits, the cracks and what the monumental masons call of the terraces, or veins of a foreign matter, which stop it and prevent that one cannot work successfully.

|

|

The gesture

Size measures displacement

By the end which enters the rock and which must open there it is a little larger than by the medium: there was a small point very with this end, to four coins.

Tools, lifting and transport

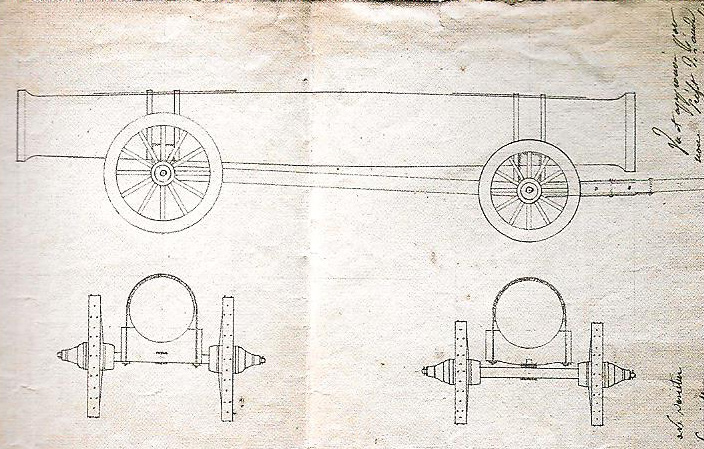

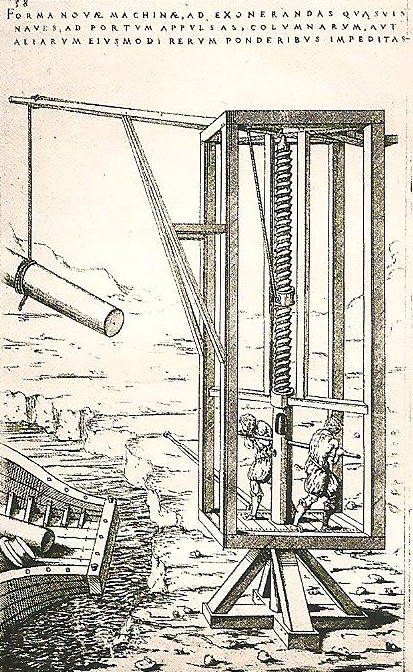

Clever machines

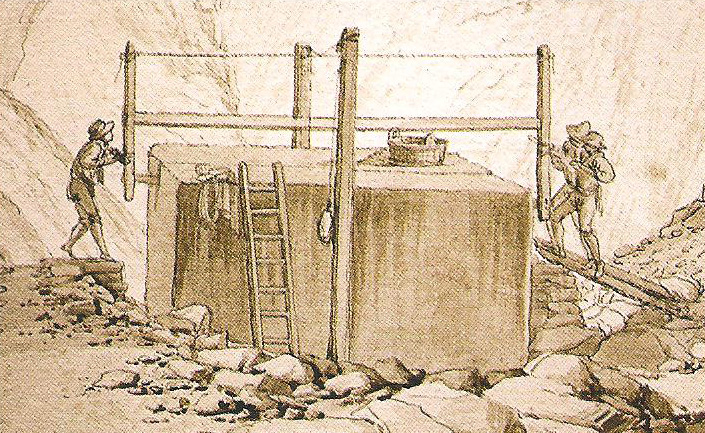

To raise and move heavy marble parts, machines as clever as curious were invented, like this swivelling crane with arm designed for the loading of column. Engraving extracted the mathematical and mechanical instruments of Jacques Besson 1594.

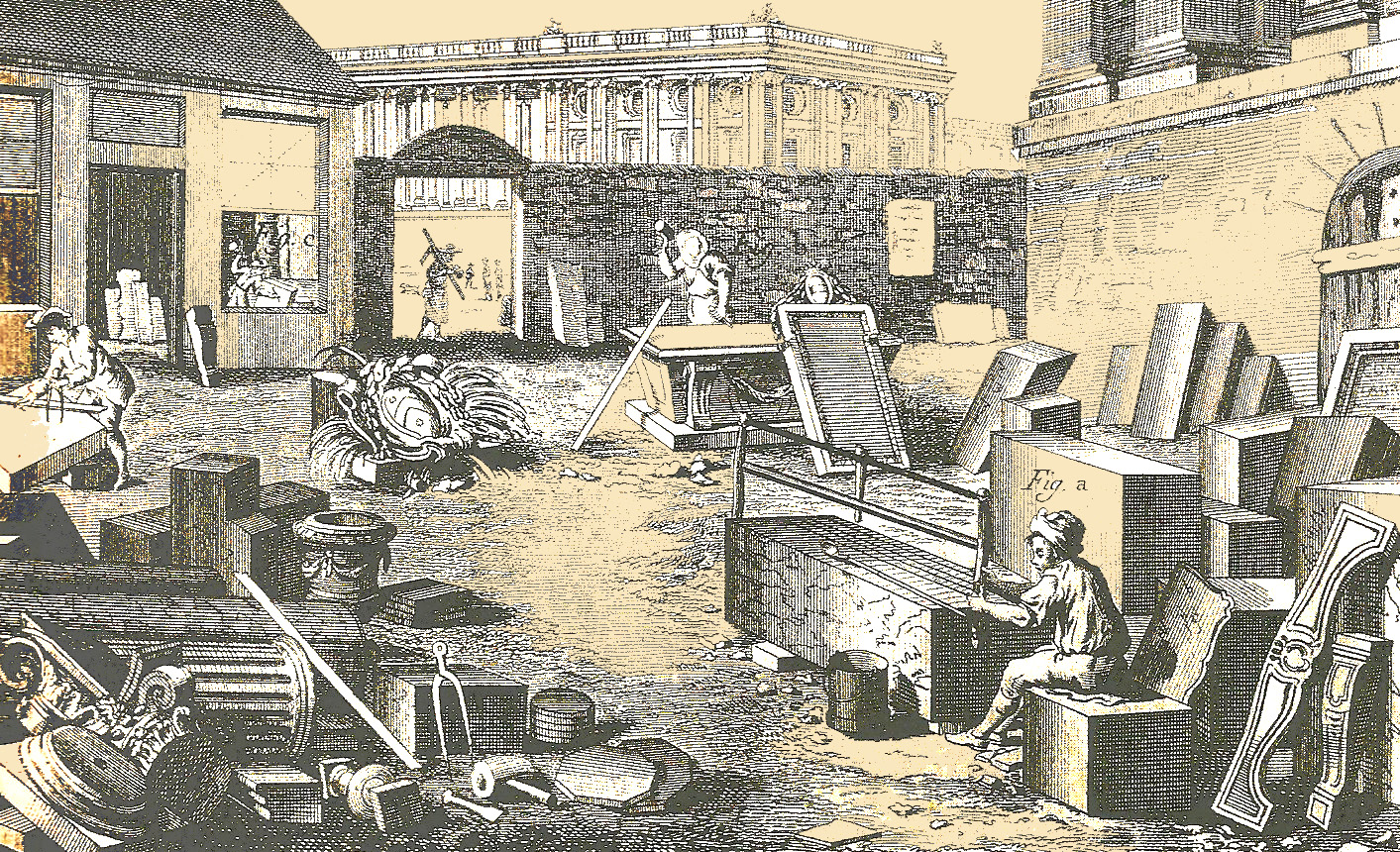

The ultimate transformation of the matter, entrusted to the monumental masons, raised of also old techniques and as complexes as those of the carriers. If all cannot be detailed, the cutting and the polishing of the panels are worth to be exposed, because they offer a summary outline of the art of the marble-mason's yard. To polish, or to reform all that can be against exactitude, with the purity and the elegance of the style, gives to the marble its ultimate brilliant aspect of a plain and luminous language, if appreciated in the palaces of God and the men.

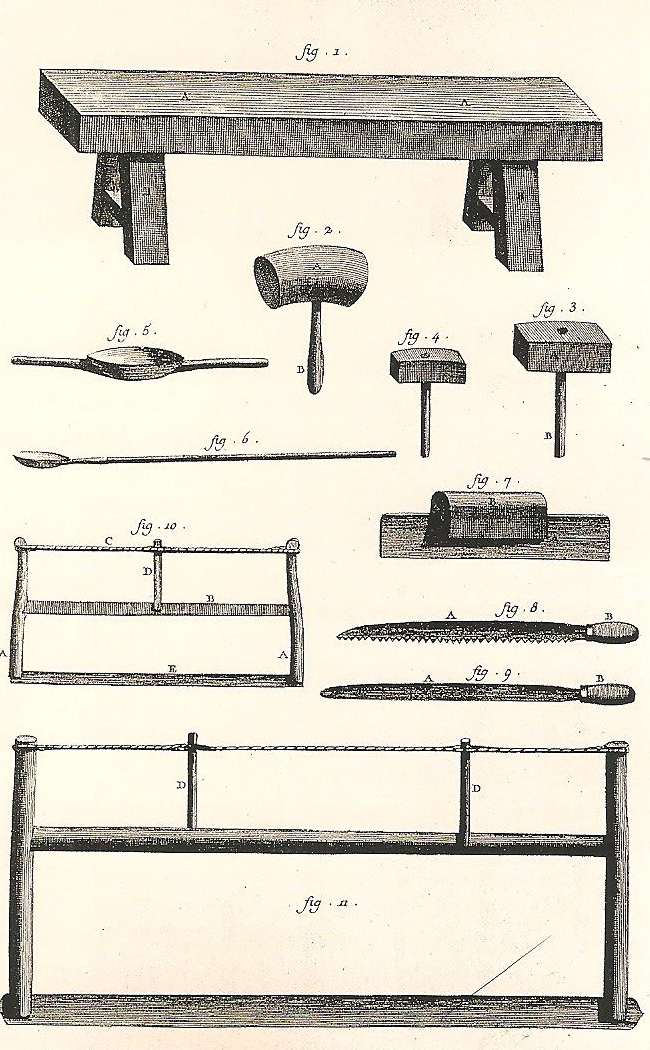

Raising, or put flat, was done with the double point, the gradine, then with the chisel, on the plates and small parts where it was necessary to slice the defects and asperities without striking too hard. For the full or stronger parts and for the final approach, one used the bush-hammer or the marteline, with which surfaces finely were studded and linked.

polishing, in the monumental masons, was carried out by the apprentices and the blue-collar workers in the family workshops, it was carried out by women and children. It was carried out like sawing by friction, but it was necessary to pass from coarse abrasives, which sandpapered or ate the parts, to finer which glossed them. In addition to siliceous sand, it could be a question of stones to be sharpened and sandstone initially, of emery then.

With bets the blocks were sawn in the stores of the king, by blue-collar workers under the orders of the director or with the expenses of the monumental masons, then there or in workshop, they were profiled, carved and polished, transformed into capitals, planks, cornices, vases balusters, chimneys, casings, furnace bridges, panels, flagstones or squares, like illustrates it this engraving of the encyclopaedia of Diderot and Alembert of 1773, presenting the store nearest to Louvre.